Ensured wastewater effluent compliance at textile print company

Introduction.

There is an increasing worldwide consumer demand for printed textiles and Honduras is committed to expanding their domestic industry. The South American textile print company Index has set out to satisfy this demand for the North American and international market. With over 400 employees and in business since 1993, the company exclusively delivers high quality consumer goods to prominent brands such as Under Armour and O’Neill.

The problem.

Large quantities of solvents and tightened effluent requirements needed a solution. The process of textile screen printing requires ample amounts of solvents which leave the factory as wastewater. These compounds, such as alcohols and aldehydes, are difficult to degrade biologically or by other means. Due to tighter effluent requirements, the factory was in dire need of an effective solution, especially since the facility could not build a new treatment plant due to restricted available space.

The solution.

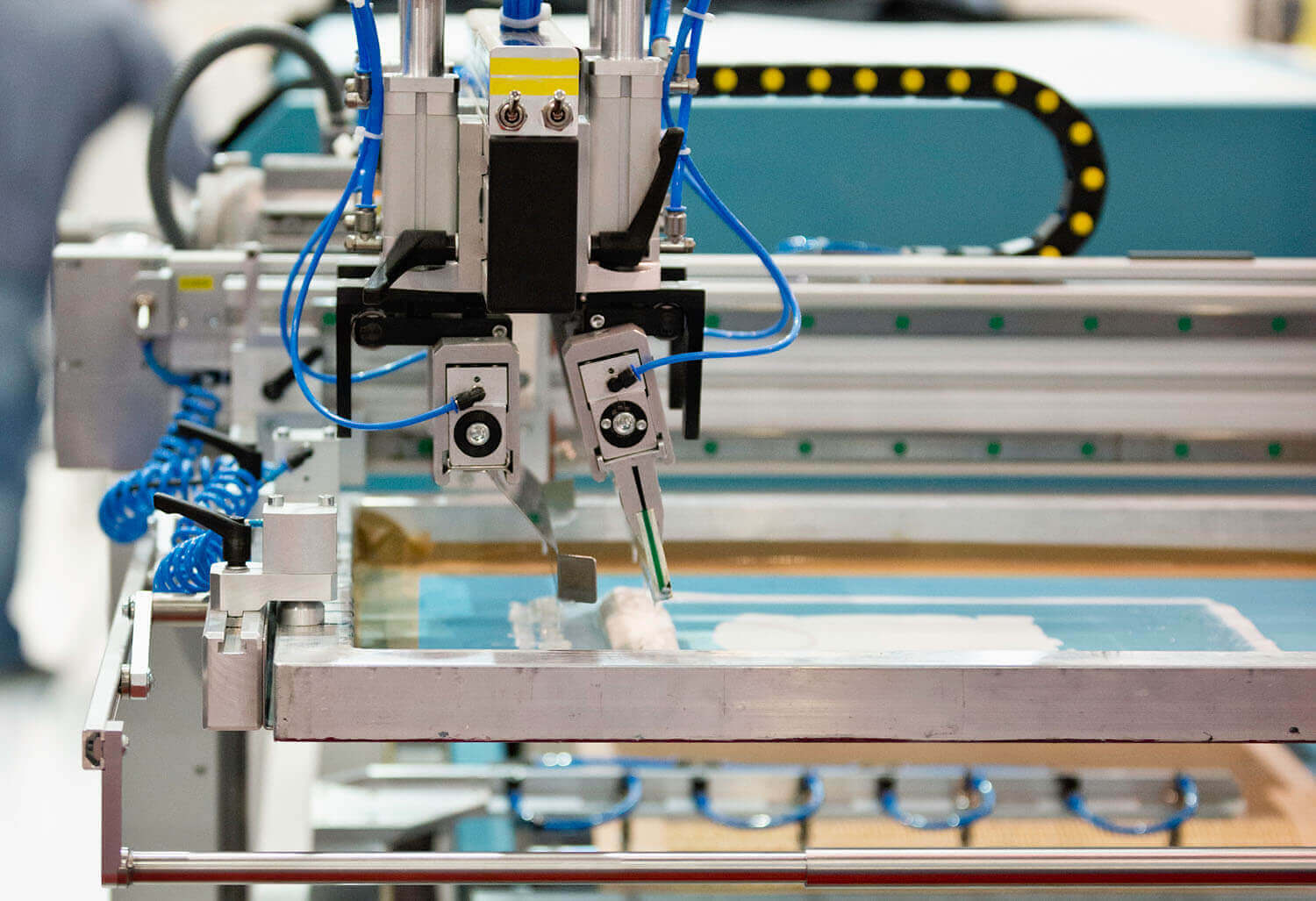

Pilot project and extensive treatment trials led to a highly tailored full scale system. Index contacted Mellifiq in search for an efficient treatment system. In order to evaluate the required capacity, our pilot project consulting services were employed. Our engineers treated actual wastewater, sampled directly from the effluent stream, using our in-house pilot facility. Following extensive treatment trials, incorporating filtration, pH control and ozone oxidation, a full scale system was designed.

The system includes our Ozonetech RENA Tellus X1000 water treatment system, foam collection, and monitoring and controls. The solution was delivered with built-in capacity redundancy for future increase of wastewater loads.

Evaluation.

Levels now reduced below the new requirements. The system was installed and successfully commissioned on site by our engineers, including connections to the collection tank, sensor installation with calibration, and start-up of ancillary equipment such as cooling system, foam collection system and ozone dissolution optimization. The ozone system handles 25 tons of high concentration wastewater per day.

The result of the effective oxidation is clear. After installation, COD and BOD levels were reduced to below 20 ppm, below the environmental regulations enforced upon the facility. The performance is continuously monitored through integrated ORP sensors and frequent lab testing of biological and chemical oxygen demand.