Request a qoute.

Avoid aroma compound cross-contamination in the beverage industry

In the beverage and brewery industry, operators and quality managers grapple with aroma (flavor) compounds cross-contamination. In mineral water production, aromas used for flavored products are often transferred between production cycles since they may be difficult to remove. In the brewing industry, espeically at plants where both beer and cider are produced in the same fermentation and filling machines, flavor compounds may transfer into beer. These quality issues are often combatted with long and intense cleaning cycles using large amounts of chemicals at relatively high concentrations.

The result from using strong aroma compounds may result in cider-tasting beer, or natural water with orange or blueberry secondary taste due to previous production batches. Flavor compounds are prone to be absorbed by sealing materials present in all process equipment such as heat exchangers, flavor mixing tanks or pipe connections.

The flavor compounds

Flavor substances (synonymous with aroma compounds) are typically esthers or aromatic compounds with multiple instances of double or triple covalent bonds. There may be hundreds of different aroma compounds in fruits and synthetic or extracted substances used in the beverage industry today. The table below shows a number of typical compounds and their respective characteristics.

| Name | Description | Chemical structure |

|---|---|---|

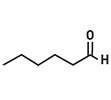

| Hexanal | Common naturally occuring substances which gives a sense of bitter almond. |  |

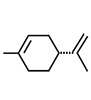

| Limonene | Compunds used for orange and lemon beverages or bottled water production. |  |

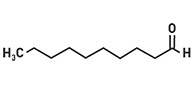

| Decanal | One of the major aroma compounds in citrus. |  |

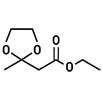

| Fructone | Used for apple and pineapple flavoring. |  |

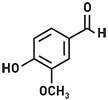

| Vanillin | Vanilla flavor. |  |

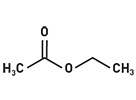

| Ethyl acetate | Also named ethyl etanoate and gives a sweet smell use in many food and beverage products. |  |

Flavour & aroma treatment

One of the most striking similarities between almost all flavor compounds is that they contain at least one double-covalent bond and in many cases aromatic rings. Ozone reacts instantly at double covalent bonds in organic substances and allows for a chain reaction involving radicals and oxidation byproducts. While the reaction typically oxidizes the aroma substances completely into carbon dioxide and water, the mere partial break-down removes the flavor effect. This process is similar to the very effective disinfection mechanisms ozone provides in the field of water treatment.

Ozone treatment of aroma transfer

As mentioned above, aroma compounds are prone to remain in the process equipment following production. Ozone cleaning, typically as a part the CIP process, provides an effective method to remove the flavor effect in the instance of unwanted aroma compounds transfer between production batches. A typical ozone concentration for most effective removal of flavors is around 3 ppm in water phase in the CIP fluid. A typical application is the rinse the process equipment with ozonated water. Please read more about how to perform CIP with ozone technology and filling machine and bottle rinsing.