Request a qoute.

The most effective way of treating water while eliminating pathogens and pollutants

Mellifiq offers premium disinfection technologies through our in-house design and production of ozone systems. The ozone system can be readily installed to a side-stream of an existing water treatment system or in-line. Mellifiq also offers complete water treatment systems. Therefore, we have experience in established technologies like UV-treatment and chlorination. The following text will provide some fundamentals in water disinfection to give a better understanding of the best available technology for different cases.

Ozone advantage in water disinfection

Disinfection of water using ozone is advantageous compared to more traditional methods, such as chlorine or UV disinfection. Firstly, ozone is more effective at deactivating viruses and bacteria than any other disinfection treatment, while at the same time requiring very little contact time, thus reducing the overall treatment residence time while simultaneously leaving no chemical residues.

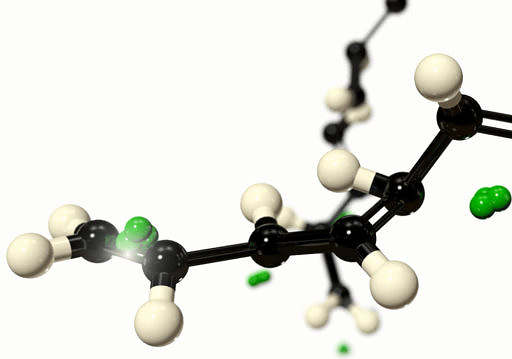

Due to the high oxidation potential, ozone will effectively degrade microbes and virus, causing cell membrane rupture and decomposition of essential biomolecular components in for example bacteria. As can be seen in the image below ozone can be used to oxidize hydrocarbons of cellular lipid bi-layers to kill contaminant microbes. There are essentially no harmful residuals from ozone use, as ozone undergoes a natural decomposition in water.

Ozone treatment also prevents re-growth of micro-organisms, provided that the other processes in the disinfection process have been successful in reducing particulates in the wastewater stream. Ozone is also produced on site and does not require shipping or handling, thus removing complications like safety and environmental issues associated with chemical handling.

Disinfection efficiency

As already stated above ozonation will enable efficient disinfection. The disinfection efficiency is commonly measured using the CT-value (concentration multiplied by time).

Ozonation provides protection against essentially all toxic and harmful unwanted microbes. In the table below the CT-values for a range of germs are listed.

| Microorganism | Required dose, CT-value (mg.min/L) |

|---|---|

| Bacillus | 0.1 |

| Clostridium botulinum spores | 0.4 |

| Cryptosporidium | 7 |

| E. coli | 0.5 |

| Encephalomyocarditis virus | 0.25 |

| Giardia cycts | 0.5 |

| Legionella pneumophila | 0.1 |

| Polio virus type 1 | 0.5 |

| Pseudomonas | 1.5 – 2 |

| Salmonella | 0.1 – 0.4 |

| Staphulococcus | 1.5 – 2 |

| Streptococcus | 0.1 |

Disinfection summary

In order to compare various disinfection agents, a brief summary table is presented below for various common types of microbes typically used for benchmarking by the US EPA and WHO for disinfection efficiency among different methods.

Benchmarking table for comparison of various disinfection agents and their efficiencies using CT-value (mg.min/L)*. Adopted from US EPA, CDC and WHO.

Generally it can be said that spores are much more resistant. They generally show CT-values about ten to fifteen times higher than the active form. It is also important to mention that in most cases there is a disinfection “threshold”. Up to this point the treatment will have a limited or low effect on the microorganisms. However above the threshold value essentielly all microbes of the same species will be destroyed.

In the image below a comparison between ozone and chlorination alternatives is shown.

| Type | Log inactivation | Ozone | Hypochlorite | Chlorine dioxide | Free chlorine | Peracetic acid (PAA) |

|---|---|---|---|---|---|---|

| E. coli | 2 | <0.02 | 25-30 | <1 | <0.05 | 25-30 |

| Viruses | 4 | <0.1 | <0.1 | 25-30 | 6 | Scarce studies |

| Protozoa | 3 | 1-2 | 10-20 | 15-25 | >100 | Scarce studies |

*It is important to note that the measurability of CT-values are not exact and that research reports different inactivation efficiency, but with consistent relative values. Use the table above as indication.

Common water disinfection technologies

There are a variety of technologies to disinfect fluids and surfaces. Mellifiq can supply several disinfection technologies with the emphasis on environmental friendly solutions. These technologies are:

- Ozonation – Dissolving a low concentration of ozone into the water, providing rapid and efficient water disinfection.

- Ultraviolet (UV) – Irradiating the water with UV-beams.

- Chlorination – Dosing chlorine compounds to the water resulting in a residual disinfecting chemical concentration.

- Other technologies include e.g. bromine, peracetic acid, iodine, copper and silver ions, potassium permanganate, fenols, detergents, hydrogen peroxide, ultrasonication, and heat.

Water disinfection techniques

Every technique has its specific advantages and its own application area. In the table below some of the advantages and disadvantages are shown. Attributes for each technology are ranked from 1 (weak) to 5 (strong):

| Technology | Ozone | UV | Chlorine Dioxide | Chlorine Gas | Peracetic Acid | Hypochlorite |

|---|---|---|---|---|---|---|

| Environmentally friendly | 5 | 5 | 3 | 1 | 2 | 1 |

| By-products | 5 | 5 | 2 | 1 | 2 | 1 |

| Efficiency | 5 | 3 | 3 | 2 | 2 | 2 |

| Investment | 2 | 3 | 4 | 4 | 4 | 4 |

| Operational costs | 5 | 4 | 3 | 4 | 4 | 4 |

| Fluids | 5 | 4 | 5 | 3 | 3 | 3 |

| Surfaces | 5 | 5 | 1 | 1 | 1 | 1 |

| Residual Disinfection | 3 | 1 | 5 | 5 | 4 | 5 |

| Handling | 5 | 4 | 3 | 3 | 2 | 2 |

| SCORE | 40 | 34 | 29 | 24 | 24 | 23 |

It is difficult to make a general comparison to represent all applications and water qualities. However, as can be seen in the table above, when comparing typical water disinfection attributes ozonation stands out as an environmentally friendly, robust, compatible, and effective water disinfection treatment.

Water disinfection applications

In the table below a few applications can be found:

| Technology | Applications and Industries |

|---|---|

| Ozone disinfection | Process feed and effluent water Drinking water Ultra pure water Surface disinfection Pharmaceutical industry Swimming pool Legionella treatment Continous residual disinfection og e.g. piping |

| UV disinfection | Process feed and effluent water Drinking water Ozone destruction Ultra pure water Surface disinfection Swimming pool Legionella treatment |

| Chlorination | Drinking water Swimming pool Residual disinfection of e.g. piping |

Disinfection prerequisites

Drinking water disinfection is linked to other water purification steps. Proper disinfection can only take place when the water is sufficiently pretreated. In many cases the disinfection process is one of the final steps in a water treament system. In for example drinking water treatment the disinfection step is preceeded by screening, sedimentation, flocculation, and sand filtration. At this point the water will be suitable for final disinfection.

Dissolved and unsoluble particulates should be removed from water, since they may cause disinfection byproducts (especially when using chlorination) and also since the particles may contain substrate (food) for pathogenic growth. Moreover, microorganisms are harder to remove from water when they are adsorbed to particles. The concentrations of undissolved particles in water should be reduced below 1 mg/l prior to disinfection.

Other chemical compounds from human or natural sources also influence the performance of the disinfection treatment. The substances may react with disinfectants to disinfection byproducts. This may increase the amount of required disinfectant to remove microorganisms and virus. It will also lead to difficulties in maintaining a residual concentration.