Request a qoute.

Sustainable and effective pre-treatment and disinfection in bottled water production plants

Ozone treatment in bottling plants has had a pivotal role since 1970’s when the bottling industry was introduced. The challenges faced in the bottling industry were in production, sterile handling and storage due to the contamination with explosive growth in microorganisms. This had a significant impact on taste, odor, and health problems due to lack of disinfection in bottled water.

In 1982, the Food and Drug Administration (FDA) classified ozone as safe for disinfection applications and as part of Good Manufacturing Practice (GMP). The permissible residual ozone concentration in bottled water can reach up to 0.4 ppm. Thereafter many health organizations have approved ozone as a key component in the bottled water industry, for example WHO. Recent changes in legislature and industry guidelines have increased the need of ozone in breweries. Ozone is safe to use in water bottling plants while leaving no residual or taste in bottled water according to International Bottle Water Association (IBWA) guidelines.

Treatment for Disinfection

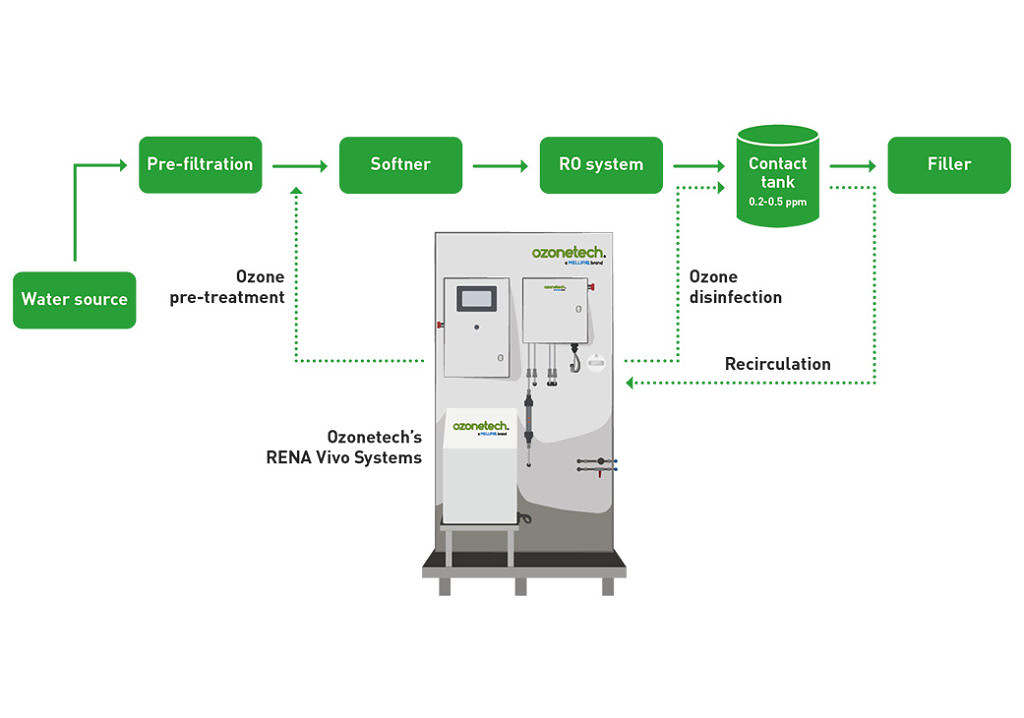

The schematic representation of ozone treatment and its possible advantages in bottling plants are shown in the figure.

Ozone as a pre-treatment step

Ozone systems can be used at pre-treatment process steps to assist in removal of iron, sulfur, manganese, color, bacteria, taste and odor. Pre-ozonation reduces fouling and development of biofilm which reduces the maintenance costs. The overall treatment system needs to be adapted to the quality of the water source. However, ozone will always be a central treatment and sanitation step to avoid unwanted taste in the final product, which will be the result if chemicals such as chlorine are used.

Ozone as disinfection step

Ozone is an exceptional chemical-free disinfectant and a powerful oxidant. More information about how ozone treatment and disinfection works can be found here. In bottled water ozonation, the ozone system is controlled to maintain a specific dissolved ozone concentration during a set contact time, which provides powerful disinfection before the bottling step. The reaction time to allow for the desired disinfection and/or oxidation processes is typically 0.2-0.5 ppm during 5-20 minutes. Our systems rapidly achieve high dissolved ozone concentration and oxidation potential with our integrated control system which makes Ozonetech’s RENA Vivo systems the number one choice for bottled water disinfection.

During the ozone disinfection step a protective environment is created against bacteria, viruses and parasites such as Cryptosporidium & Giardia cysts in the treated water. In addition, ozone is very effective against undesired taste and odor. More detailed information on water disinfection using ozone can be found here.

Ozone versus chemical disinfection in bottling plants

While ozone is a common technology for sanitizing water before the filling process, some plants still use chemicals such as sodium hypochlorite (NaClO) to maintain a microbe-free system. The table below summarizes the differences between these two methods.

| Characteristics | Ozone | Hypochlorite (HClO–) or other chemicals |

|---|---|---|

| Disinfection potency (CT, mg/L.min) | 0.05-1 | 0.1-10 |

| Typical concentration during use (mg/L) | 0.1-0.3 | 0.3-0.6 |

| Residues | None | Yes, requires UV destruction to remove unwanted taste |

| By-products | None | May develop cancerogenic by-products unless all organic material is removed |

| pH regulation | Not required | Should be regulated to 6.5-7 to maintain highest disinfection efficiency |

| Mechanical equipment | RENA Vivo ozone system | Dosing pump, chemical storage tank, miscellaneous logistics equipment |

| Consumables | 1-2 kW | Chemical consumption, dosing pump power, acid for pH control |

RENA Vivo – The turn-key system for bottled water

Mellifiq specializes in providing the bottled water industry with completely integrated systems including high-performance ozone generator, oxygen supply, advanced controls, ozone destruction, and degassing in one turn-key system. Typically, our RENA Vivo A- or B-series range is sufficient to fulfil the high standards of sanitation in the bottled water process. Read more about our RENA Vivo segment here.

- Our ozone systems have an efficient oxidation potential and is superior to other available chemical disinfectants

- Treatment provides low operating- and no chemical cost

- We make sure repeatability becomes reliability with the highest results every time in accordance with clients requirements

- Ozone by itself can remove disinfection byproduct effectively

- Generate a successful return of investment with very low maintenance

Our ozone systems are easy to install with only two hydraulic connections which can be connected to the bottling plants water buffer tank, in-line or as a side stream to the main feed line. All sensors for controlling desired dissolved ozone levels are integrated into the design. The RENA Vivo system operate at highest possible efficiency at more than 25 gDO/kWh (grams of dissolved ozone per kilowatt hour). All mechanisms for safe use are built-in, such as degassing valve, ozone destructor and ambient ozone detectors.