Multiphase ozone scrubber removes odors at leading food ingredient producer

Introduction.

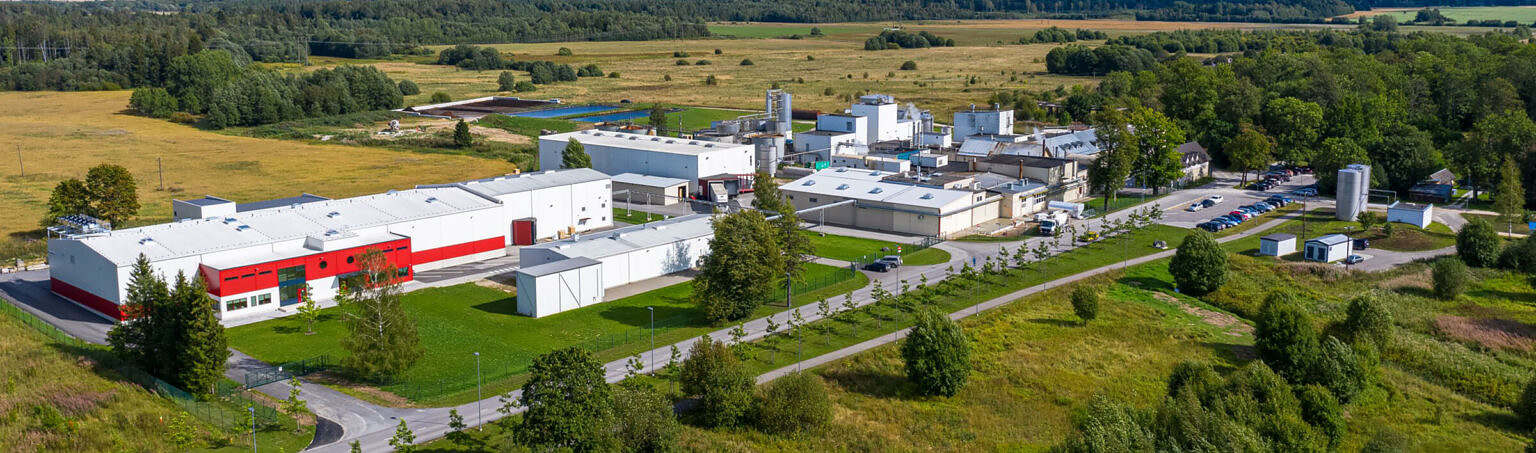

Our client, one of the key producers of food ingredients in Estonia had problems with disturbing odors for a long-time which brought about many complaints from the residents in the surrounding areas. The discomfort, caused by odors from the production process and wastewater, eventually became unbearable. The company, which is very successful, is experiencing a continuous growth in the operations. Due to strict local regulations our client needed an effective high-end odor removal system. Hence, the company turned to Mellifiq inquiring about a long-term and sustainable solution.

The problem.

Fermentation is one of the steps in our client’s production process. Microorganisms process the raw materials while releasing volatile compounds in the fumes. These compounds have a very intense odor, due to their chemical structure, particularly perceptive for the human nose. High humidity levels make the treatment even more challenging. Even if the production plant is not in a central location, odors were spreading, leading to complaints from the neighbors. Due to increasing pressure from the local authorities, the production manager decided to install an odor control system for ensuring requirement compliance.

The solution.

In this case, Mellifiq needed to take a larger approach than traditional product delivery. Due to technical requirements and space limitations, there was no standard product compliant with all requirements, hence we developed a custom-made solution. A water scrubber with ozonation was the selected technology. In this setup, ozone had a double function, as it was injected in both air and water. When dissolved into the water phase, it was preventing contamination due to bacteria such as Salmonella and Legionella. Air-phase ozone removed the remaining odors after the water scrubber, thus completing the odor treatment. A maximum height of only 2.3 m was one of the most challenging space limitations. CFD (Computational Fluid Dynamics) was the tool used to solve this issue. The simulations ensured an effective combination of air-water contact with optimal air velocity. The scrubber was fully integrated with the ozone system, with a smooth operation over time. The Ozonetech RENA Tellus X600 was the selected system for this case, as it has the output needed in Mellifiq’s product portfolio. With a modular design, the system is prepared for even higher odor loads for future operation.

Evaluation.

After tailoring the design, the delivery was completed with the ozone system and the main scrubber components. Thanks to Mellifiq’s turn-key approach to system design and automation, the whole solution could be installed with ease. As soon as the system was commissioned, a whopping 94% odor removal rate was measured. The neighbors received the greatest benefits, which caused the complaints to cease. After observing results going above expectations, the production manager quickly decided to order the same solution for another site in Slovakia, that was suffering from the same problem. We are glad to see our efforts rewarded with a satisfied and recurring customer.