Request a qoute.

The effectivity of our ozone systems lives up to the and highest industry standards and recommendations

In addition to the obvious benefits of cleaning the exhaust air from kitchens and restaurants, industry standards and recommendations are essential to take into account in order to achieve a safer and more pleasant working environment. Standards and recommendations aim to harmonize the requirements for technical solutions and the entrepreneurs delivering them.

EN 16282 – New EU standard for ventilation in commercial kitchens

EU’s new standard for equipment in commercial kitchens is long-awaited and well-produced. It covers everything from the hood to the point of discharge. It took 14 years to finalize and aims to harmonize competition within the EU as well as setting quality requirements for functionality, safety and the environment.

Air purification technologies are described in part 8 where requirements are defined for equipment for treating kitchen exhaust air. The air treatment reduces fire hazards as well as problems with odors. It is also a prerequisite for installing heat exchangers in the exhaust air stream enabling heat recovery.

The new EU standard has had a great response and is quickly spreading across Europe resulting in a considerable reduction of energy consumption and carbon dioxide emissions. A driving force is the Ecodesign Directive, which states that heat recovery used in real estates shall have a minimum thermal efficiency of 68% for batterybased heat exchangers and 73% for plate-/ countercurrent heat exchangers by January 1, 2018.

The new EU standard – a step closer to sustainable commercial kitchens

The EN 16282 standard for ventilation in commercial kitchens was released in autumn 2017. This section aims to describe and discuss the new regulations and requirements for commercial air treatment methods. Before choosing your treatment method, take a minute to read this.

Smart demands for increased quality, safety and a greener world

EU’s new standard for equipment in commercial kitchens is long-awaited and well-produced. It covers everything from the hood to the point of discharge. It took 14 years to finalize and aims to harmonize competition within the EU as well as setting quality requirements for functionality, safety and the environment.

Air purification technologies are described in part 8 where requirements are defined for equipment for treating kitchen exhaust air. The air treatment reduces fire hazards as well as odors. It is also a prerequisite for installing heat exchangers in the exhaust air stream enabling heat recovery. The methodology is now spreading in Europe and will considerably reduce energy consumption and carbon dioxide emissions.

A driving force is the Ecodesign Directive, which states that heat recovery used in real estates shall have a minimum thermal efficiency of 68% for batterybased heat exchangers and 73% for plate-/ countercurrent heat exchangers as of January 1, 2018.

The eight sections of the new EU standard EN 16282*

- General requirements

- Kitchen ventilation hoods

- Kitchen ventilation ceilings

- Air inlets and outlets

- Air ducts

- Aerosol separators

- Fixed fire extinguishing systems

- Installations for treatment of aerosols;

requirements and testing

*EN 16282 Equipment for commercial kitchens. Components for ventilation in commercial kitchens. The EU standard EN 16282-8 can be obtained from your National Organization for Standardization.

We have read the standard thoroughly and what follows is a summary of how some of the treatment technologies are affected.

The ecodesign directive – a focus on energy usage

The Directive was adopted by the EU in 2005 and is aimed at reducing energy usage, and thereby greenhouse gas emissions by 20%.

General requirements for purification techniques

- For technical safety reasons, components immersed in the air stream shall be designed to withstand a constant temperature of at least 60 °C. The exhaust air may, therefore, require cooling.

- The installation must be easy to access for maintenance and cleaning purposes

- Components exposed to UV-radiation or ozone should comprise of suitable materials

- If ozone is emitted at ground level, concentrations must be below the applicable limit values

- If ozone sensors are used, they shall be labelled “OZONE SENSOR” and have a unique traceable calibration certificate

- Connections between the ozone generator and the kitchen exhaust duct must be visibly labelled “OZONE” every ten meters

New requirements for ozone generators

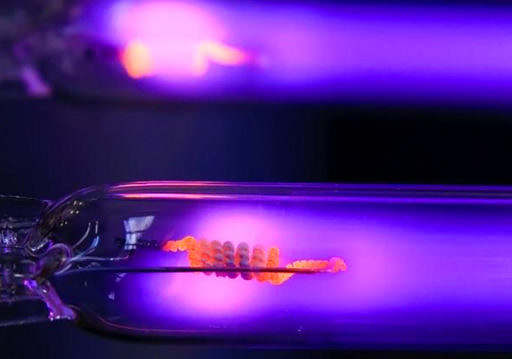

For ozone generators fed with oxygen (for example, our high-performance RENA system), there are now several new smart requirements.

- Installation, repair and maintenance shall be carried out by personnel educated by the manufacturer

- The ozone generator shall only be in operation when the exhaust fan is running

- Suitable equipment, such as flow and/or pressure sensor(s), shal l ensure that ozone is not released into the building. If the system is equipped with a pressure sensor, it needs to be set up so that the ozone system is shut down should the differential pressure fall below 20 Pa

- Inspection hatches on the exhaust duct shall carry a warning sign that reads: “WARNING — Ozone Treatment”

New requirement for air-fed ozone generators

In addition to the general requirements for commercial air treatment technologies and ozone generators, the standard specifies that oxygen-fed ozone generators shall be used for total exhaust airflows exceeding 2,500 m3/h. The reason for this is that air-fed ozone generators produce too high amounts of nitrogen oxides and nitric acid. The standard states:

“NOTE: To safe-guard against NOx and HNO3 build-up in the extract air, an oxygen-fed ozone generator will be used for a total extract flow exceeding 2500 m3/h.”

New requirements for photocatalytic air treatment (often called ozone-free UV light treatment)

- F9- filter (ISO 16890, ePM1 80%+) shall be fitted prior to the photocatalytic system. The filter must be resistant to ozone and UV. The filter shall not be fitted in the kitchen hood/ceiling

- For UV lamps, the maximum operating temperature specified by the manufacturer should not be exceeded

- Hoods equipped with UV lamps shall carry a visible warning sign: “WARNING — UV radiation”

- Inspection hatches on the exhaust duct shall carry a warning sign that reads: “WARNING — Ozone Treatment

Note! As this technology contains both UV and ozone, the requirements for each treatment technology must also be taken into account.

Here are the requirements you can ask for

- Capacity to remove air-borne grease during high airflows

- Minimum requirement for manual cleansing of ducts

- Simple to install the distribution of the ozone – even when the ducts are difficult to access

- Capacity to treat air with high grease content

- Low energy consumption

- The ozone distribution should not interfere with the activities of the kitchen nor be aesthetically disturbing

- Stable and consistent treatment capacity

- Low operational costs

- The ozone system should be able to be installed where it is out of the way of the activities being undertaken in the premises

- Ability to prevent grease build-ups in ducts

- Minimum lifespan of 20 years

- Remote 24/7 monitoring to detect any interference

- Does not disturb the ventilation balance

- Lowest total cost of all purification technologies over time

- The system should include an ozone sensor which turns off the system if ambient ozone levels exceed set threshold. The sensor shall be supplied with a uniquely traceable calibration certificate

- No components installed in the air flow

- The purification system should turn on/off when the ventilation system turns on/off

- One single system should be able to treat several kitchens in, for example, a food court

- High operational reliability

- Stepless variable treatment capacity

- For larger projects with high treatment requirements, several ozone systems should be able to be installed together

- Minimum maintenance requirements

- Easy adjustment of treatment capacity

- Comply with requirements of EN 162882

- Minimum service requirements

- Easy to upgrade the system’s total capacity

You are always welcome to contact us if you have any questions about the standard or if you are interested in our solutions and ozone treatment in general.

Swedish imkanal 2012:2

Imkanal 2012:2 is the latest update of the recommendations the ventilation industry together with organizations and authorities produced in 2010.

The recommendation is based on regulatory requirements as well as general advice in Boverket’s building rules and fully takes into account, among other things The Swedish National Board of Housing and Work Environment’s instructions and guidelines for the rules.

The update contains in part higher requirements regarding the use of ozone generators, UV light or equivalent technology. Ozonetech is very positive to the new implemented regulations. The news related to ozone in Imkanal 2012:2 is mainly:

- The risks of corrosion in the system are highlighted. The recommended material choice is now stainless steel quality for those parts of the duct channel installation that are directly affected by high ozone concentrations. Established players always prescribe stainless steel or any other ozone-resistant material in conduit ducts between the ozone generator and the flue channel where high levels of ozone can occur.

- The risk of transferring gases during heat recovery is highlighted. Modern heat exchangers essentially eliminate all risk of leakage between exhaust air and supply air, provided that the pressure balancing over the unit is adjusted correctly with higher pressure on the supply air side than the exhaust air side. You can also supplement the recycling system with carbon filters on the supply air side after the unit to achieve even better indoor air quality.

- The importance of a safe work environment is emphasized. The recommendations state that the user must be taken into account, ie the kitchen staff. This is achieved through the use of an ozone sensor, located in the kitchen. An ozone sensor ensures that a good working environment is maintained. In addition, all installations of ozone generators, UV light or similar technology should be interlocked over fans, pressure switches, cleaning shutters or the like.

In addition to the above mentioned news, Imkanal 2012:2 follows the recommendations that were previously given. Thus, as long as adequate ozone aggregates, UV light or equivalent technology is used for purification, the recommendation is still that the choice of material for the duct system may be any galvanized/stainless steel or sheet metal.

Ozonetech welcomes the stricter requirements set out in the recommendations and appreciates that the industry also wants to take an active role in a safer work environment. With these recommendations, the work to achieve our vision of the modern large kitchen can continue – a kitchen that consumes considerably less energy than before but which is at the same time more fireproof, offers working people a good working environment and has little impact on residential accommodation. In short: a kitchen in harmony with its surroundings.

Imkanal 2012:2 has been prepared by the Swedish Chimney Sweep Master’s National Association, the Contracting Companies, the Swedish Agency for Social Protection and Preparedness, the Swedish Technical Research Institute, Fire Protection Sweden, Lindab, Fläkt Woods, Hallströms Workshops, Profiduct, Swedish Ventilation, Paroc.

Keep in mind that the Imkanal 2012:2 is a Swedish industry guideline for the Swedish kitchen exhaust ventilation designers and installers and the guidelines for you country may differ.

The Swedish Work Environment Authority, Boverket and Brandkonsulten AB have submitted comments on the industry recommendation. Are you curious and want to know more? Book one of our courses at Mellifiq Academy and we’ll tell you more.