Request a qoute.

Treatment of Chemical and Biological Oxygen Demand (COD and BOD) requires expert engineering capabilities

The chemical oxygen demand (COD) is a measure of the amount of oxygen to oxidize non-inert constituents in a water sample in a standardized chemical test procedure. Similarly, the biological oxygen demand is the amount of consumed dissolved oxygen used by bacteria to metabolize biodegradable constituents under a standardized time-period, such as 5 or 7 days (BOD5 and BOD7). Both methods of analysis is an international approach to determining the contamination level or potential detrimental impact if released into the environment untreated.

Biodegradable vs non-biodegradable COD

Non-biodegradable COD is the fraction of soluble substrates which would not be degradable by microorganisms. Some of the examples include pharmaceuticals (diclofenac, paracetamol and propofol), persistent organic pollutants (pesticides, industrial chemicals and hormones) and other molecules including fluorinated and bromated organic compounds. Please note however that the biodegradable COD measurement value through COD-Cr or COD-Mn methods may not be equal to the measured BOD value since different measurements techniques are applied. The table below shows some typical compounds and their characteristics in terms of COD and BOD demand.

The various definitions, their meanings and impact may be difficult to differentiate at first glance. Mellifiq holds the relevant expertise to assess your effluent challenges and proper treatment capacities required to solve your specific needs.

It should also be emphasized that the COD or BOD value does not reflect the composition of the substances present in a particular water sample, and the type of treatment needed to reduce COD and BOD may differ significantly.

Common industries that grapple with high levels of COD and BOD – and who face release charges or penalties – are for example the pharmaceutical industry, municipal wastewater treatment plant or reclamation facilities, breweries, food & beverage producers and off-shore platforms.

Due the vast differences in how the wastewater in these industries is produced, various technologies need to be applied and tailored to each situation. Mellifiq assesses each situation and applies extensive experience in process design in combination with an extensive array of brands such Ozonetech ozone technology, Saniray UV systems or WaterMaid filtration systems.

| Compounds | BOD5/COD ratio | COD:O3 ratio |

|---|---|---|

| Pharmaceuticals | 0.1 | 6:1 to 3:1 |

| Persistent organic pollutants | 0.2 | 5:2 to 2:1 |

| Aldehydes | 0.3 | 7:1 to 4:1 |

| Amines | 0.5 | 4:1 to 3:1 |

Different types of COD-generating compounds and their estimated ozonation requirements. A low BOD:COD ratio normally represents a compounds that is not readily biodegradable and may be in need of a tailored solution.

How to treat COD and BOD?

It must be taken into account that one type of technology may not be optimal to reduce the measurable COD or BOD in a wastewater stream. This depends on a number of factors pertaining to the amount of particles, level of contamination and the types of substances which cause measurable value. While one technology may be suitable to remove a fraction, achieving most or all of the COD or BOD requires a multi-technology approach.

WaterMaid FlexKarb-S for for particle removal

While the different sources and industries produce wastewater with varying properties, an untreated wastewater stream typically contain suspended particles in the form of inert constituents such as sand, clay, sludge or other NOM. These suspended particles may make up up to 40-70% of the total COD and 20-50% of the BOD. Mechanical filtration to remove such particles can be a valuable tool to help reach the bottom line downstream in the treatment process and Mellifiq often apply WaterMaid FlexKarb-S automated filtration systems as a key unit operation in solving the customer needs.

Ozonation a power tool for treating complex substances

A large fraction of most industrial and municipal wastewater COD or BOD often originates from dissolved organic compounds (DOC) and may have various chemically complex structures whose. High level of complexity may render many methods impervious to effective treatment. Ozonation is in many situations a powerful treatment method if designed, sized and operated properly. Mellifiq offers complete ozone systems meticulously engineered to face many types of high grade wastewater effluent streams, exclusively delivered to the market from our Ozonetech brand, such as RENA Vivo or tailored RENA Tellus X turn-key ozone systems.

The tables below gives some guidelines into the sizing approach for some typical substances found in industrial wastewater and estimated COD and BOD values in select industries.

| Compounds | BOD5/COD ratio | COD:O3 ratio |

|---|---|---|

| Fatty acids | 0.4 | 2:3 |

| Nutrients (ammonia, organic phosphate) | 0.6 | 7:1 |

| Proteins | 0.7 | 6:2 |

| Alcohol | 0.9 | 5:3 |

| Sugars | 0.7 | 4:2 |

Estimated sizing guideline for various types of compounds found in industrial liquid waste streams which generate elevated levels of COD and BOD.

| Oxygen demand type (mg/L) | Domestic wastewater | Food & beverage | Chemical & pharmaceutical |

|---|---|---|---|

| BOD5 | 200-300 | 450-1100 | 250-1000 |

| COD | 450-700 | 1450-2200 | 2000-18750 |

Typical levels of COD and BOD from different plants, all of which can be addressed through proper assessment, design and implementation by Mellifiq.

AOP-based solutions

AOPs are advanced oxidation process utilizing extremely reactive species for the destruction of pollutants. Formed radicals have higher oxidation potential than for example ozone and reaction rates which are significantly higher, thus leading to lower contact time and footprint. AOP can also be applied to achieve complete- or partial oxidation of the pollutants in the treatment process.

Mellifiq normally applied ozone-catalytic or ozone-UV-based AOP to enhance the formation of radicals, either with turn-key RENA Tellus Y (catalytic ozone based AOP) or combined with the Saniray Zeeron UV line, or with peroxide-ozone systems. A few examples of reaction mechanisms in formation of hydroxyl radical with ozone are shown below.

Effective adsorption by WaterMaid FlexKarb-C systems

While mechanical filtration and ozone based treatment combined solutions are often sufficient to achieve very high COD and BOD removal rates, polishing methods are sometimes considered for some types of stable molecules, such as PFAS and PFOS, or to complement other treatment technologies to eliminate any residuals left. Such polishing methods may be adsorption through multimedia filtration systems, like Mellifiq’s WaterMaid FlexKarb-C product line, or nanofiltration (NF) and reverse osmosis (RO). Depending the molecular polarity of the wastewater substances subject to treatment, Mellifiq tailors the solution in WaterMaid FlexKarb system via a large range of filtration media targeted specifically for the constituents at hand.

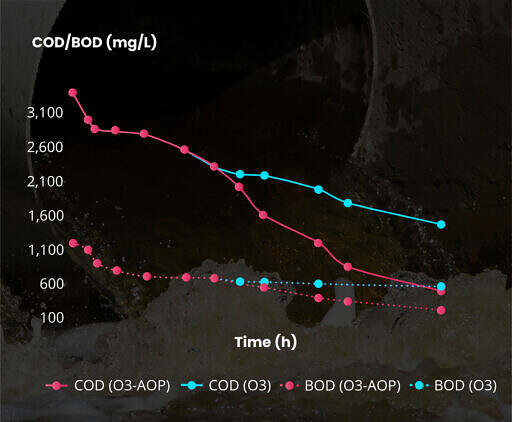

Display of enhanced reaction rates with COD with a catalytic-ozone COD process compared to same water with only ozonation.

A WaterMaid FlexKarb-C system installed in a containerized solution from Mellifiq alongside a tailored RENA Tellus X200 system for tertiary treatment at a water reclamation facility.

| Ferric oxide | Fe3++ O3 → (FeO)2++OH– + O2 + H+ |

|---|---|

| Hydrogen peroxide | O3 + H2O2 → OH– + O2 + H2O |

| Ultraviolet | O3 + H2O → O2 + H2O2 (In the presence of UV) 2O3 + H2O2 → 2OH + 3O2 |

A complete treatment process is key to successful COD and BOD removal

Mellifiq has taken the stance to be the total solutions provider for solving our clients needs for COD and BOD treatment in all industries requiring our services and expertise, taking a holistic approach to delivering solutions. This entails careful examination of the problem at hand and combining the best available technology to address various wastewater characteristics. We achieve this by listening to the customers’ needs and utilizing our complete range of products, systems, consulting capabilities and experiences. We offer a multitude of available services such as pilot projects, rental solutions and complete contracting capabilities to ensure the process design exceeds expectations.

Related reference project.

Micropollutant Removal at Klippan Wastewater Treatment Plant

Ensured wastewater effluent compliance at textile print company